Introduction of High Current Products

We are familiar with whole business of the design, manufacturing installation of the high current bus bars which be used in the electric arc furnace, the caustic soda electrolytic plant, the graphite making plant, aluminium smelter plant, and so on in Japan and overseas especially we have over 90% of the market shares in Japan.

We provide design, manufacturing, installation of feeder(bus bar) for feeding to the super-conductive coil which confines the high temperature plasma of the nuclear fusion generation, said as the future generation of electricity power steady-state.

We provide the construction of the electric power company, substation of 66 kV ~ 500 kV and delivery of electric equipment, design, construction, including engineering of the other factory substation of 66 kV ~ 275 kV.

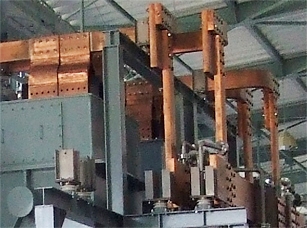

Water Cooled Copper Busbar (DC Conductor for Electric Arc Furnaces)

High currents of between 10 kA and 200 kA are used in the production of caustic soda produced by brine electrolysis and magnesium chloride used as a catalyst for titanium.

We design the circuits for energising such high currents, manufacture the products, deliver products, and installation on site that meet the customer's needs.

The picture on the above shows an example of a water cooled copper busbar.

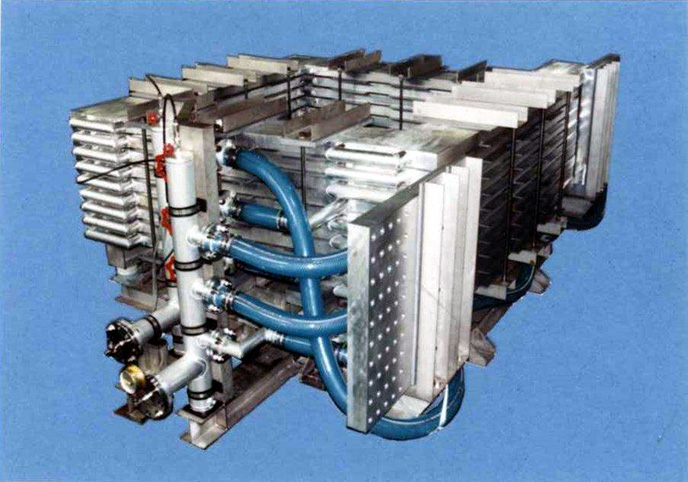

Air Cooled Aluminium Busbar (Prefabricated)

The picture on the above shows manufactured products.

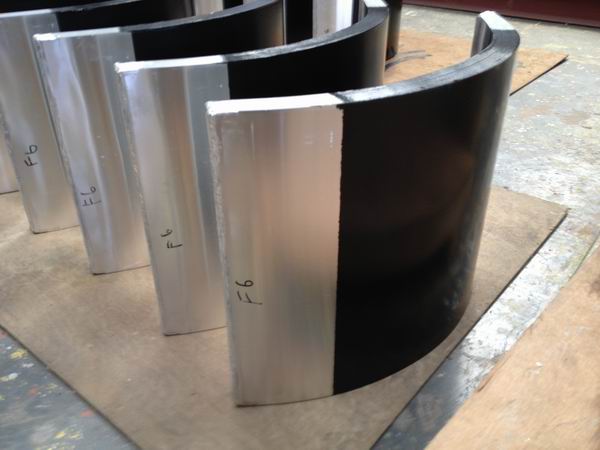

DC Shunt for Current Measurement

CTs and shunts are often used as instruments for measuring large currents, but CTs and shunts are affected by the surrounding magnetic field and it can be difficult to measure precise currents. Even when shunts are used, precise current measurement is not possible at high currents of around 30,000 A due to a large temperature rise.

By using a copper block with good conductivity for the conventional manganin resistance, reducing the temperature rise and capturing the precise temperature change of the manganin, a shunt that can measure with an error of 0.5% even at 30 kA has been developed and will be delivered.

DC Reactors

DC power made from AC by a rectifier is not a perfect DC wave, and even during 6-phase rectification, a large amount of AC is mixed into the waveform. This AC content and large current waveform fluctuations, such as switching surges, can have a negative impact on surrounding equipment and can damage the thyristors that are the elements of the rectifier.

DC reactors protect equipment from these adverse effects. In addition, even water-cooled reactors are manufactured from welded aluminium with a large wall thickness that does not leak water, as is the case with conventional products, reducing operating costs and greatly simplifying maintenance.

Movable Rigid Trolley Lines

The picture on the above shows installed on subway lines.

Aluminium Flexible Bus bar

The picture on the above shows manufactured products.

Water Cooled Copper Tube Bus bar

The picture on the above shows manufactured products.

Copper-Steel Power Conducting Arm

The picture on the above shows manufactured products.

Water Cooled Cables for Electric Arc Furnaces

The picture on the above shows delivered to our customer.

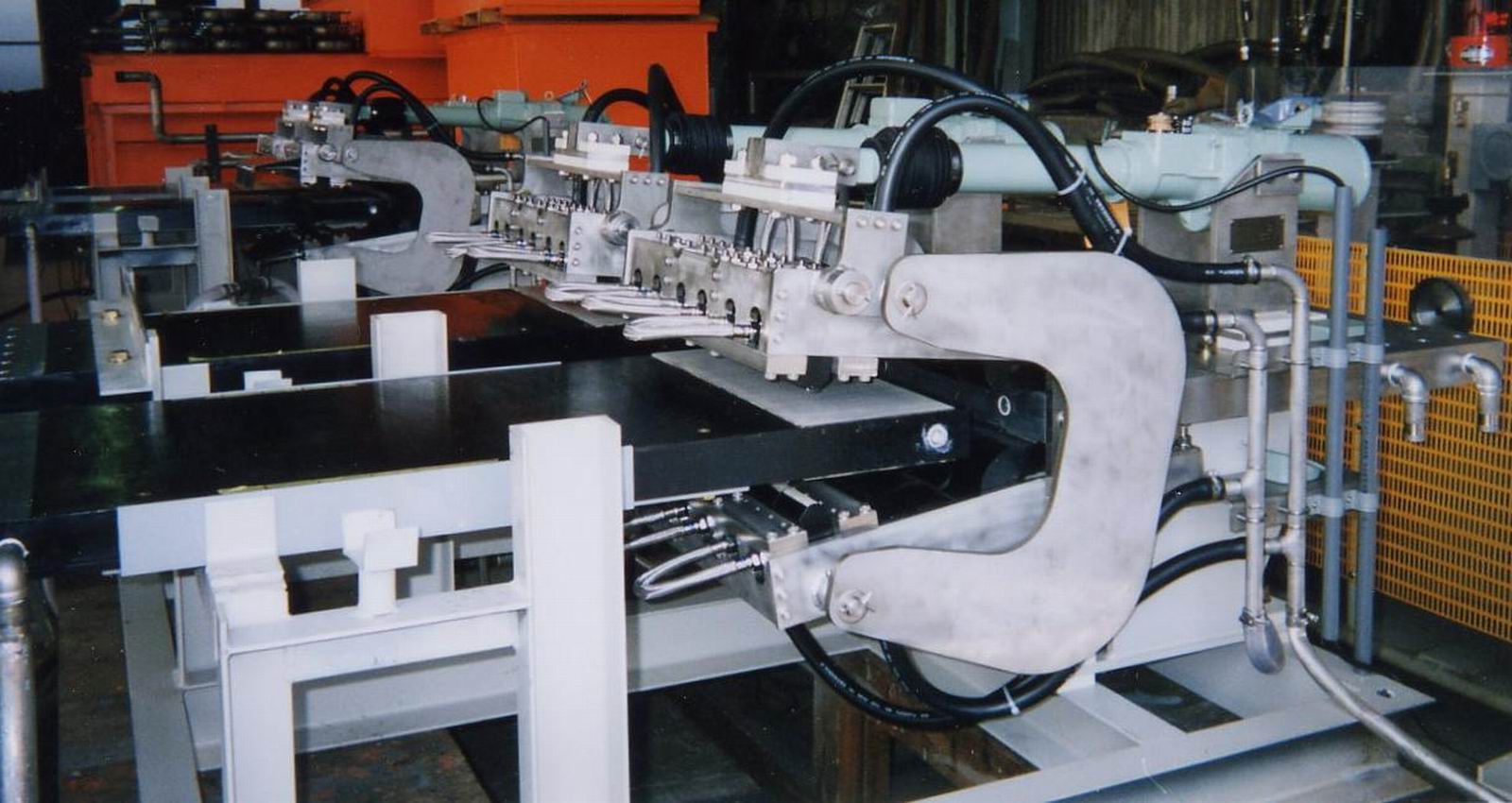

Movable Contact DC high current switcher

In graphitisation furnaces for producing graphite electrodes, high currents may be energised while absorbing thermal elongation of the electrodes, and equipment costs can be controlled by using a few power supplies to feed many furnaces.

To meet these needs, we have developed the "movable contact type, high current switching device" PAT, which can respond to changes in the energisation distance while energising high currents and can also switch power supplies. This product eliminates the need for conventional expensive high-current flexible conductors and significantly reduces equipment costs.